STRANDED LOOSE TUBE

Stranded Loose Tube GYFTY

| Type:GYFTY |

|

| Optic Fibre in loose tube non-metallic FRP filling compound for SZ stranded cable cores PE outer sheath kevlar reinforcement. |

| Application Range |

| For long distance and local communications with strong electromagnetic field effect. |

| Installation Method |

| for aerial mounting, or in pipe, tunnel, cable furrow, etc. |

| Application Temperature |

| -40~+70 |

| Features |

With low attenuation loss and dispersion, the reasonable design and precision control on fibre length in loose tube ensures better mechanical performance and adaptability to environment of FOC.

The close structure of SZ layer stranding prevents optic fibre from stress under bad environment.

It could ensure moisture and water resistant performance of FOC with filling compound filled outside strength member and inside cable core with better pliability.

The cable is of non-metallic structure, light and convenient for mounting, with better performance against electromagnetic effect. |

|

Technical Parameters

| FOC Core(S) |

FOC OD(mm) |

FOC Weight(kg/km) |

Min. Bending Radius(mm) |

Min. Tension Allowed (N) |

Min. Crush Pressure (N/100mm) |

| Static |

Dynamic Short |

Short Term |

Long Term |

Short Term |

Long Term |

| 2~36 |

11.0 |

98 |

110 |

220 |

1500 |

600 |

1000 |

300 |

| 38~72 |

12.5 |

130 |

130 |

260 |

1500 |

600 |

1000 |

300 |

| 74~96 |

13.5 |

170 |

140 |

280 |

1500 |

600 |

1000 |

300 |

| 98~120 |

14.2 |

210 |

150 |

300 |

1500 |

600 |

1000 |

300 |

| 122~144 |

15.0 |

260 |

160 |

320 |

1500 |

600 |

1000 |

300 |

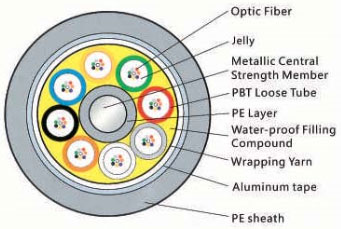

Stranded Loose Tube GYTS

| Type:GYTS |

|

| Optic Fibre in loose tube metallic central strength member filling compound for SZ stranded cable cores plastics coated steel tape and PE sheath bound together stranded steel wire for self supporting unit |

| Application Range |

| For long distance and local communications. |

| Installation Method |

| aerial |

| Application Temperature |

| -40~+70 |

| Features |

With low attenuation loss and dispersion, the reasonable design and precision control on fibre length in loose tube ensures better mechanical performance and adaptability to environment of FOC.

The close structure of SZ structure stranding prevents optic fibre from stress under bad environment.

It could ensure moisture and water resistant performance of FOC with filling compound filled outside strength member and inside cable core.

It could ensure much better moisture and shootig resistant performance of FOC with corrugated steel tapewrapping.

It could ensure high tensile strength with stranded steel wire as self supporting unit. |

|

Technical Parameters

| FOC Core(S) |

FOC OD(mm) |

FOC Weight(kg/km) |

Min. Bending Radius(mm) |

Min. Tension Allowed (N) |

Min. Crush Pressure (N/100mm) |

| Static |

Dynamic Short |

Short Term |

Long Term |

Short Term |

Long Term |

| 2~36 |

11.8 |

158 |

120 |

240 |

1500 |

600 |

1000 |

300 |

| 38~72 |

13.4 |

194 |

140 |

280 |

1500 |

600 |

1000 |

300 |

| 74~96 |

14.9 |

235 |

160 |

320 |

1500 |

600 |

1000 |

300 |

| 98~120 |

16.6 |

310 |

170 |

340 |

1500 |

600 |

1000 |

300 |

| 122~144 |

18.2 |

359 |

190 |

380 |

1500 |

600 |

1000 |

300 |

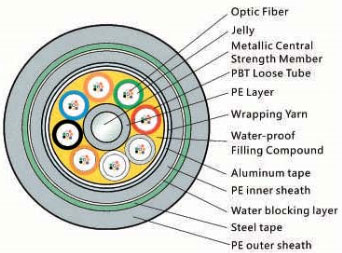

Stranded Loose Tube GYTA53

| Type:GYTA53 |

|

| Optic Fibre in loose tube metallic central strength member filling compound for SZ stranded cable cores corrugated steel-plastics compound tape and PE inner sheath bound together.Corrugated steel plastics compound tape and PE outer sheath bound together. |

| Application Range |

| For long distance and local communications. |

| Installation Method |

| Direct burial |

| Application Temperature |

| -40~+70 |

| Features |

With low attenuation loss and dispersion the reasonable design and precision control on fibre length in loose tube ensures better mechanical performance and adaptability to environment of FOC.

The close structure of SZ layer stranding prevents optic fibre from stress under bad environment.

It could ensure moisture and water resistant performance of FOC with filling compound filled outside strength member and inside cable core.

With better pliability it could ensure high tensile strength, better performance of resisting side press and animal biting with double corrugated metallic layers wrapping and double sheath. |

|

Technical Parameters

| FOC Core(S) |

FOC OD(mm) |

FOC Weight(kg/km) |

Min. Bending Radius(mm) |

Min. Tension Allowed (N) |

Min. Crush Pressure (N/100mm) |

| Static |

Dynamic Short |

Short Term |

Long Term |

Short Term |

Long Term |

| 2~36 |

15.9 |

250 |

170 |

340 |

3000 |

1000 |

3000 |

1000 |

| 38~72 |

17.4 |

290 |

180 |

360 |

3000 |

1000 |

3000 |

1000 |

| 74~96 |

19.1 |

342 |

200 |

400 |

3000 |

1000 |

3000 |

1000 |

| 98~120 |

20.7 |

420 |

210 |

420 |

3000 |

1000 |

3000 |

1000 |

| 122~144 |

22.3 |

475 |

230 |

460 |

3000 |

1000 |

3000 |

1000 |

Stranded Loose Tube GYTC8S

|

| Type:GYTC8S |

|

| Optic Fibre in loose tube metallic central strength member filling compound for SZ stranded cable cores.Plastics coated steel tape and PE sheath bound together stranded steel wire for self supporting unit. |

| Application Range |

| For long distance and local communications. |

| Installation Method |

| Aerial |

| Application Temperature |

| -40~+70 |

| Features |

With low attenuation loss and dispersion the reasonable design and precision control on fibre length in loose tube ensures better mechanical performance and adaptability to environment of FOC.The close structure of SZ layer stranding prevents optic fibre from stress under bad environment.

It could ensure moisture and water resistant performance of FOC with filling compound filled outside strength member and inside cable core.It could ensure much better moisture and shooting resistant performance of FOC with corrugated steel tape wrapping.

It could ensure high tensile strength with stranded steel wire as self supporting unit. |

Technical Parameters

| FOC Core(S) |

FOC OD(mm) |

FOC Weight(kg/km) |

Min. Bending Radius(mm) |

Min. Tension Allowed (N) |

Min. Crush Pressure (N/100mm) |

| Static |

Dynamic Short |

Short Term |

Long Term |

Short Term |

Long Term |

| 2~36 |

11.8 |

275 |

120 |

240 |

8000 |

6000 |

3000 |

1000 |

| 38~72 |

13.4 |

311 |

140 |

280 |

8000 |

6000 |

3000 |

1000 |

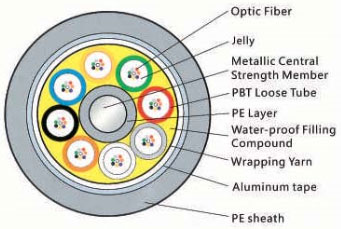

Stranded Loose Tube GYTA

|

| Type:GYTA |

|

| Optic Fibre in central loose tube cable core filled with filling compound 12 pieces of steel wire evenly stranded around loose tube plastic-coated steel tape bound with PE sheath |

| Application Range |

| For long distance and local communications. |

| Installation Method |

| In pipe, or aerial, or mounting |

| Application Temperature |

| -40~+70 |

| Features |

| With low attenuation loss and dispersion the reasonable design and precision control on fibre length in loose tube ensures better mechanical performance and adaptability to environment of FOC with light weight and convenient for laying with better pliability. Steel wire armour ensures better crush-resistant performance .Cable core wound with corrugated AL tape ensures better moisture proof performance. |

Technical Parameters

| FOC Core(S) |

FOC OD(mm) |

FOC Weight(kg/km) |

Min. Bending Radius(mm) |

Min. Tension Allowed (N) |

Min. Crush Pressure (N/100mm) |

| Static |

Dynamic Short |

Short Term |

Long Term |

Short Term |

Long Term |

| 2~36 |

11.6 |

138 |

120 |

240 |

1500 |

600 |

1000 |

300 |

| 38~72 |

13.1 |

167 |

140 |

280 |

1500 |

600 |

1000 |

300 |

| 74~96 |

14.9 |

206 |

160 |

320 |

1500 |

600 |

1000 |

300 |

| 98~120 |

16.3 |

267 |

170 |

340 |

1500 |

600 |

1000 |

300 |

| 122~144 |

17.9 |

310 |

190 |

380 |

1500 |

600 |

1000 |

300 |

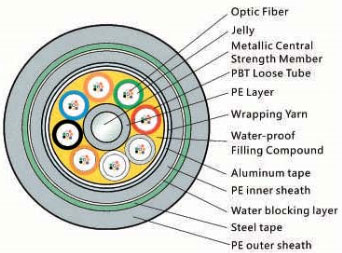

Stranded Loose Tube GYTY53

|

| Type:GYTY53 |

|

| Optic Fibre in loose tube metallic central strength member filling compound for SZ stranded cable cores PE Inner Sheath corrugated steel-plastics compond tape & PE outer sheath bound together. |

| Application Range |

| For long distance and local communications. |

| Installation Method |

| In pipe, for aerial mounting or direct burial |

| Application Temperature |

| -40~+70 |

| Features |

With low attenuation loss and dispersion the reasonable design and precision control on fibre length in loose tube ensures better mechanical performance and adaptability to environment of FOC.The close structure of SZ layer stranding prevents optic fibre from stress under bad environment.

It could ensure moisture and water resistant performance of FOC with filling compound filled outside strength member and inside cable core with better pliability.

It could ensure high tensile strength, better performance of resisting side press and animal biting with double corrugated metallic layer wrapping and double sheaths. |

Technical Parameters

| FOC Core(S) |

FOC OD(mm) |

FOC Weight(kg/km) |

Min. Bending Radius(mm) |

Min. Tension Allowed (N) |

Min. Crush Pressure (N/100mm) |

| Static |

Dynamic Short |

Short Term |

Long Term |

Short Term |

Long Term |

| 2~36 |

14.4 |

211 |

150 |

300 |

3000 |

1000 |

3000 |

1000 |

| 38~72 |

16.0 |

251 |

170 |

340 |

3000 |

1000 |

3000 |

1000 |

| 74~96 |

17.7 |

304 |

180 |

360 |

3000 |

1000 |

3000 |

1000 |

| 98~120 |

19.3 |

374 |

200 |

400 |

3000 |

1000 |

3000 |

1000 |

| 122~144 |

20.9 |

427 |

220 |

440 |

3000 |

1000 |

3000 |

1000 |